Understanding Your Needs and Applications

Before investing in a laser machine, it is essential to have a clear understanding of the specific needs and applications for which the device will be utilized. Laser machines are available in various forms, each designed for particular tasks such as engraving, cutting, or marking. Identifying your intended use is the first step in selecting the right equipment that fully meets your requirements.

The materials you plan to work with play a pivotal role in determining the type of laser technology suitable for your applications. For instance, if your focus is on cutting materials like wood, acrylic, or metal, a CO2 laser machine would be ideal due to its efficiency and effectiveness in cutting non-metal materials. In contrast, fiber laser machines are often the preferred choice for marking and engraving harder materials such as metals, thanks to their precision and speed.

Another critical aspect to consider is the complexity of the designs you wish to create. If your projects involve intricate patterns or fine details, opting for a laser machine with higher resolution capabilities is advisable. Additionally, think about the production volume that your operations will demand. Some laser systems are engineered to handle high-volume tasks efficiently, allowing businesses to scale their production without compromising quality.

Moreover, it’s important to evaluate the software compatibility of the laser machine. Various software applications can enhance the functionality of your laser equipment, catering to different design and production needs. In conclusion, by thoroughly assessing your specific needs and aligning them with the vast array of available laser technologies, you can ensure a well-informed investment decision that optimally supports your applications. This thoughtful approach not only maximizes the benefits of the laser machine but also contributes to overall operational success.

Types of Laser Machines Available

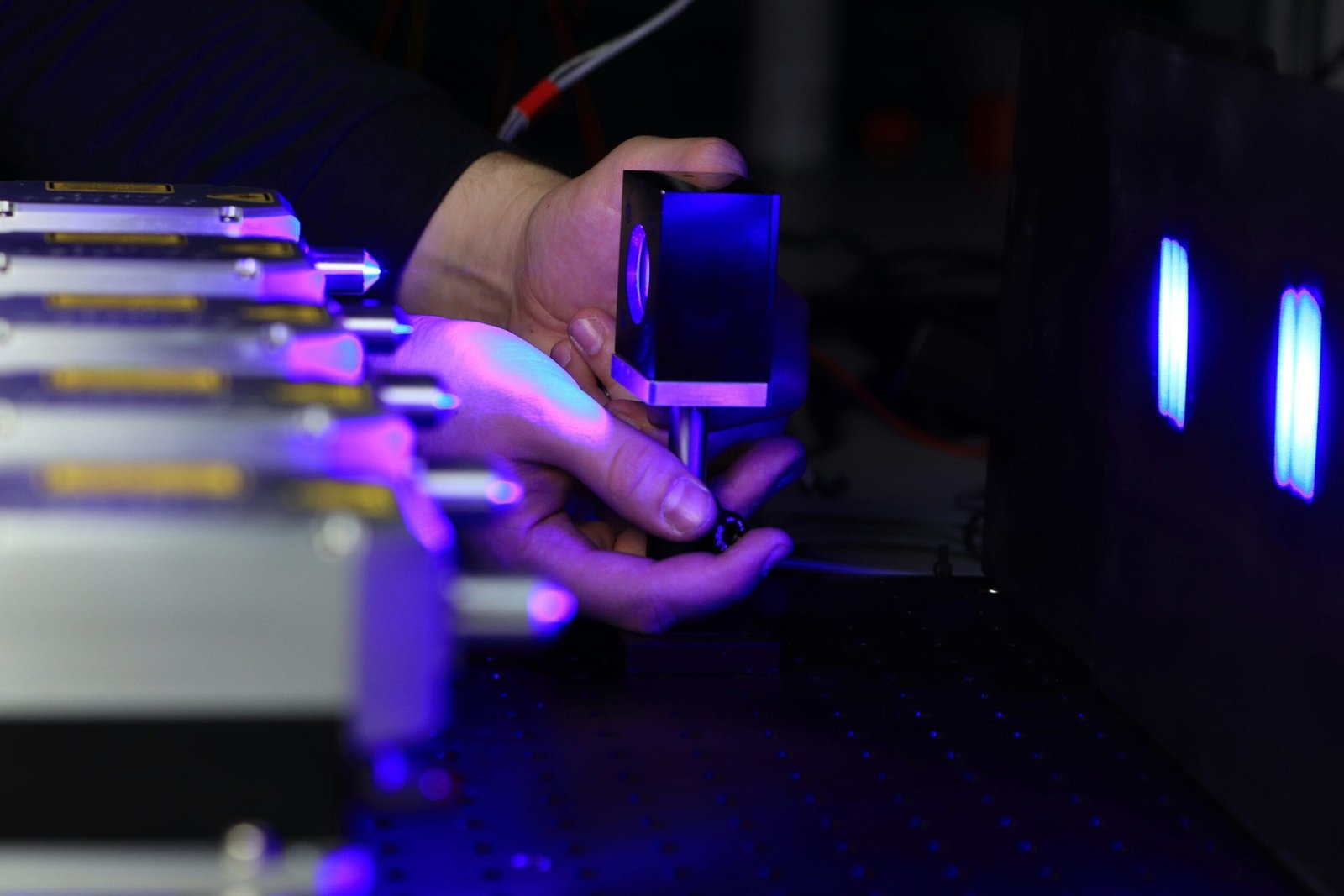

When considering a laser machine for your projects, understanding the various types available on the market is crucial. The three predominant categories are CO2 lasers, fiber lasers, and diode lasers, each designed with specific functionalities tailored to various applications.

CO2 lasers are perhaps the most versatile and widely used in industries. They operate by utilizing carbon dioxide gas, which produces a powerful beam capable of cutting, engraving, and marking a wide range of materials. These machines excel in processing non-metal materials such as wood, acrylic, glass, and leather, making them a favored choice in sectors like sign making and woodworking. However, CO2 lasers generally have a higher operational cost and require more maintenance over time compared to other types.

Fiber lasers represent a significant advancement in the laser technology landscape. They utilize optical fibers doped with rare-earth elements, producing a high-quality beam that is ideal for metal cutting and marking. The key advantages of fiber lasers include their efficiency, speed, and low maintenance requirements. They are particularly effective on metals such as aluminum, copper, and brass, making them suitable for manufacturing and metalworking applications. One downside, however, is their higher initial price point, which may deter some buyers.

Diode lasers are another option that has gained popularity due to their compact design and affordability. They are primarily used for engraving and marking purposes and are best suited for low-power applications. Diode laser machines are user-friendly and energy-efficient, making them ideal for small businesses or hobbyists. However, they may not be as effective on thicker materials or in high-volume production scenarios.

In summary, understanding the characteristics and applications of CO2, fiber, and diode lasers will enable buyers to choose a laser machine that aligns with their specific operational needs and budget constraints.

Budget Considerations and Total Cost of Ownership

When considering the purchase of a laser machine, potential buyers should be aware that the initial purchase price represents only a fraction of the overall investment involved. The total cost of ownership encompasses various factors that need to be evaluated to ensure the machine meets operational needs without unforeseen financial strain.

Firstly, the range of prices for laser machines can vary significantly based on their type, features, and capabilities. Basic entry-level machines may start at a few thousand dollars, while advanced industrial laser systems can exceed several hundred thousand. It is important to research and determine the specific type of laser machine that aligns with your operational requirements and budget constraints.

In addition to the initial purchase cost, ongoing expenses must be accounted for. Maintenance is a critical aspect that can contribute to the total cost of ownership. Regular service and repairs are necessary to keep the laser machine functioning optimally, which can entail both time and budget considerations. Furthermore, consumables such as lenses, mirrors, and gases may need replacement periodically, adding to ongoing costs.

Software and control systems are also vital components when operating a laser machine. Depending on the complexity of projects, keeping software current or investing in specialized applications may require additional expenditure. Training personnel to effectively utilize the machine is another aspect often overlooked, but investing in skills development can significantly enhance operational efficiency.

Lastly, plan for potential upgrades in technology. As advancements in laser technology emerge, evaluating options for upgrading your equipment can keep the machine competitive and efficient. In summary, understanding these various elements is crucial for making an informed decision and accurately forecasting the financial commitment required for both the acquisition and ongoing operation of a laser machine.

Supplier Reputation and Support Services

When considering the purchase of a laser machine, the reputation of the supplier plays a crucial role in shaping the overall experience and satisfaction with the product. A reputable supplier is often characterized by a history of positive customer feedback, a proven track record of reliable products, and reputable standing within the industry. Researching online reviews, testimonials, and case studies from previous customers can provide insights into the supplier’s reliability and effectiveness in delivering not only quality machinery but also support services.

Customer service is another vital component to consider. A supplier should offer responsive customer support to assist users in troubleshooting issues and answering queries related to the laser machine. Effective communication is essential, as it can greatly influence the performance and efficiency of the equipment. Additionally, a supplier’s willingness to provide training on operating the laser machine can lead to better utilization of the equipment, ensuring that users are equipped to handle their tasks proficiently.

Warranty options are significant when determining the potential longevity of the laser machine. A reliable supplier often provides comprehensive warranty coverage, which can serve as a safety net should any issues arise with the machine. Evaluate what is included in the warranty and whether the supplier is willing to support repairs or replacements as necessary.

Finally, the availability of technical support is paramount in ensuring that users can effectively address any challenges they may face during operation. Suppliers that offer ongoing technical assistance and maintenance services demonstrate commitment to their products, promoting a relationship that extends beyond the initial sale. By carefully evaluating these aspects, prospective buyers can make an informed decision and select a supplier that not only delivers quality laser machines but also stands as a reliable partner throughout their investment journey.