Understanding Your Marking Needs

When selecting a laser marking machine, the first step is assessing your specific marking requirements. Understanding the materials you intend to mark is crucial, as different types of lasers are designed for various substrates. For instance, fiber lasers are excellent for metals, while CO2 lasers are more suitable for non-metal materials such as plastics, wood, and glass. Knowing your material composition allows you to narrow down the suitable laser technology and ensures efficient and effective marking.

Next, consider the type of markings you intend to create. Whether you require text, logos, or barcodes, each marking type can demand different features from the laser marking machine. For instance, if your project involves detailed engravings or intricate designs, a machine with higher resolution capabilities will be necessary. Alternatively, if your need is primarily for alphanumeric marking, a lower-cost option may suffice. Understanding the complexity and clarity required for your markings helps in selecting the right machine that meets your quality demands.

Production volume is another essential factor to evaluate. If your business operates on a large scale and requires high throughput, you might want to consider a faster laser marking machine designed for industrial applications. On the other hand, if your marking needs are sporadic or limited, a more compact and cost-effective solution could be appropriate. Assessing your production dynamics together with other needs helps in determining the equipment that best aligns with your operational workflow. Investing time in understanding these factors not only aids in selecting the right laser marking machine but also enhances productivity and reduces costs in the long term.

Exploring Different Types of Laser Marking Machines

Laser marking machines have become essential tools in various industries due to their precision and efficiency. The primary types of laser marking technologies include fiber lasers, CO2 lasers, and ultraviolet (UV) lasers, each offering unique functionalities and advantages tailored to different materials.

Fiber lasers are renowned for their versatility and efficiency, particularly in marking metals such as stainless steel, aluminum, and brass. They produce a high-intensity beam that allows for deep engraving, offering exceptional results in industrial applications. Fiber lasers are favored for their low maintenance requirements and high operational speeds, making them ideal for high-volume production environments.

CO2 lasers, on the other hand, are best suited for non-metal materials. They excel in marking plastics, wood, leather, and glass. With a wavelength longer than that of fiber lasers, CO2 lasers are capable of engraving and cutting through a variety of substrates, creating intricate designs and detailed markings. Their ability to mark on delicate materials without causing damage adds to their popularity in industries such as packaging and signage.

Ultraviolet (UV) lasers utilize a shorter wavelength, which makes them particularly effective for applications requiring minimal thermal impact. This technology is perfect for marking sensitive materials like electronic components and certain plastics that might deform under high heat. The precision offered by UV lasers ensures that the integrity of the material is maintained while achieving high-quality markings.

When choosing the right laser marking machine, it is essential to consider the material you will be working with and the specific application requirements. Each type of laser marking technology presents distinct capabilities, opening up various possibilities in enhancing product branding and traceability. Conducting thorough research and understanding these differences enables users to align their choice with their marking needs effectively.

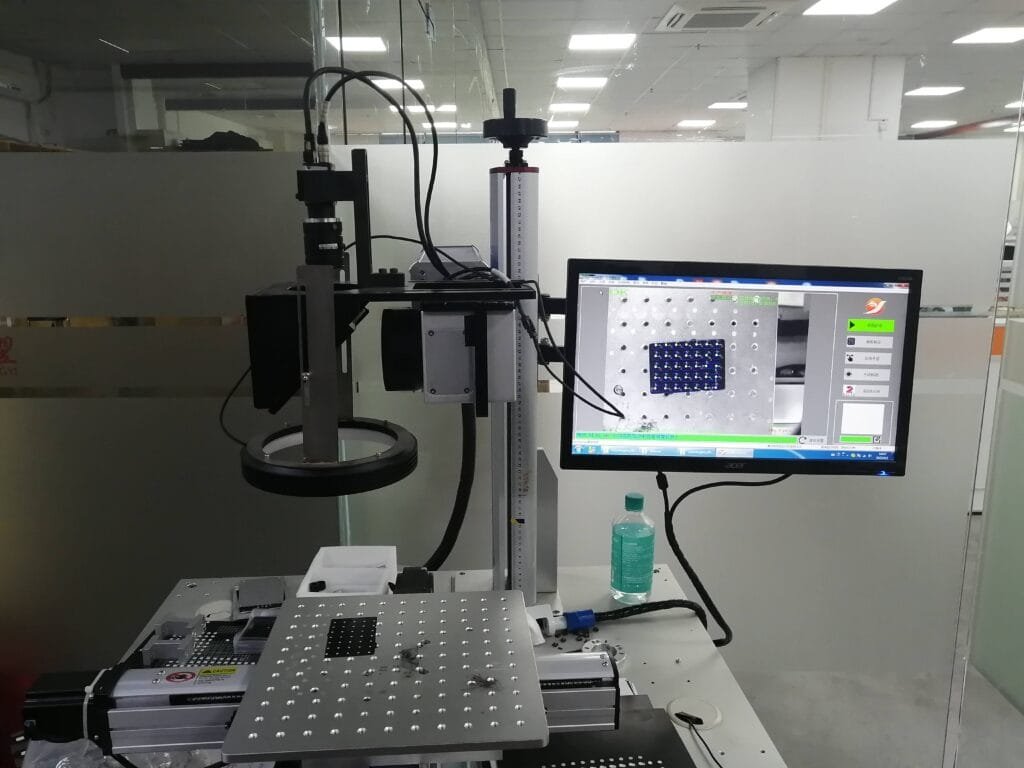

Key Features to Look for in a Laser Marking Machine

When selecting a laser marking machine, a variety of essential features and specifications must be taken into consideration to ensure optimal performance and efficiency. One of the first attributes to evaluate is the laser power. The power of the laser primarily determines the depth and speed of engraving. A higher wattage laser is generally capable of marking materials more quickly and effectively, particularly on harder surfaces. As such, assessing the specific materials you plan to engrave is critical in determining the appropriate laser power required.

Another significant aspect is engraving speed, which affects how quickly a project can be completed. High-speed engraving machines can significantly increase productivity, especially in commercial applications. Therefore, it is advisable to look for models that offer adjustable speed settings to accommodate varying material types and project requirements.

Cooling systems are also vital for sustainable operation. Effective cooling mechanisms help maintain the laser’s performance and longevity by preventing overheating during extended use. Various types of cooling systems exist, including air, water, and thermoelectric coolers, each having its benefits and applications. Understanding your operational environment and usage patterns can guide the selection of the most suitable cooling solution.

Software compatibility is crucial, too. A laser marking machine should support a range of design software to enable seamless integration with existing workflows. Compatibility with popular software programs like AutoCAD or Adobe Illustrator can significantly enhance usability and creativity in marking designs.

Lastly, consider the maintenance requirements of the machine. Regular maintenance is necessary to ensure the consistent performance of your laser marking machine. Choosing a model with easily accessible components and clear maintenance guidelines can simplify upkeep and maximize operational uptime. As you evaluate these features, you can make a more informed decision that aligns with your specific marking needs.

Budgeting and Cost Considerations

When investing in a laser marking machine, budgeting plays a critical role in selecting the right model to fit your needs. The initial purchase price is often the most visible cost; however, it is important to consider it as part of a broader financial plan that includes ongoing maintenance and operational expenses. Depending on the laser marking technology chosen, such as fiber, CO2, or UV, the initial costs can vary significantly. High-quality models may command a premium price, but their durability and efficiency often justify the investment.

Additionally, ongoing maintenance is a vital consideration. Regular servicing of laser marking machines ensures optimal performance and longevity. These costs can range from minor repairs to comprehensive annual servicing contracts. It is advisable to budget for these expenses from the outset to avoid unexpected financial strain later. Furthermore, understanding the availability of replacement parts for specific models can aid in long-term budgeting.

Operational costs are another important factor to account for, encompassing electricity consumption, consumables, and any necessary software updates. By assessing the total cost of ownership over a machine’s lifecycle, businesses can make more informed decisions that go beyond the initial investment. It may also be beneficial to explore financing options or leasing agreements, which can spread costs over time and align payments with cash flow.

Ultimately, striking the right balance between cost and quality is paramount. A less expensive laser marking machine may save upfront but lead to higher operational costs or lower productivity. Therefore, thoroughly research potential return on investment (ROI) for different models. This includes gauging increased efficiency, productivity, and how those metrics align with your business goals. Taking these budgeting and cost considerations into account will help you choose the most suitable laser marking machine for your specific applications.