Understanding Ship Descaling and Its Importance

Ship descaling is a vital maintenance process that encompasses the removal of unwanted deposits, including marine growth, rust, and other contaminants that accumulate on the vessel’s surfaces. This buildup can severely impact the operational efficiency of maritime vessels. The phenomenon is primarily attributed to environmental factors such as saltwater exposure, temperature fluctuations, and the presence of microorganisms that thrive in marine ecosystems. Over time, these factors contribute to the formation of scales that hinder the functionality and overall lifespan of a ship.

The presence of scale can lead to various detrimental effects, such as increased friction against the water, which in turn raises fuel consumption. A dirty hull, for instance, can compromise a vessel’s speed and maneuverability, resulting in higher operational costs and reduced performance. Moreover, the growth of biofouling organisms on submerged surfaces can pose significant risks, not only to the vessel itself but also to marine biodiversity. By facilitating the transfer of invasive species from one ecosystem to another, ships that are not adequately maintained can inadvertently disrupt local environments.

Addressing the issue of scale buildup is crucial not only for maritime operations but also for safety. A clean ship is essential for optimal performance, ensuring that vessels comply with safety regulations and avoid potential hazards at sea. Regular descaling procedures can prolong the lifespan of critical components, such as propellers and hulls, leading to decreased maintenance costs and reduced downtime. As advancements in technology emerge, solutions such as the laser cleaning machine offer effective methods for achieving a thorough and environmentally friendly descaling process. Such innovations are reshaping how ship descaling is approached, leading to improved results and sustainable maritime practices.

What is Continuous Laser Cleaning Technology?

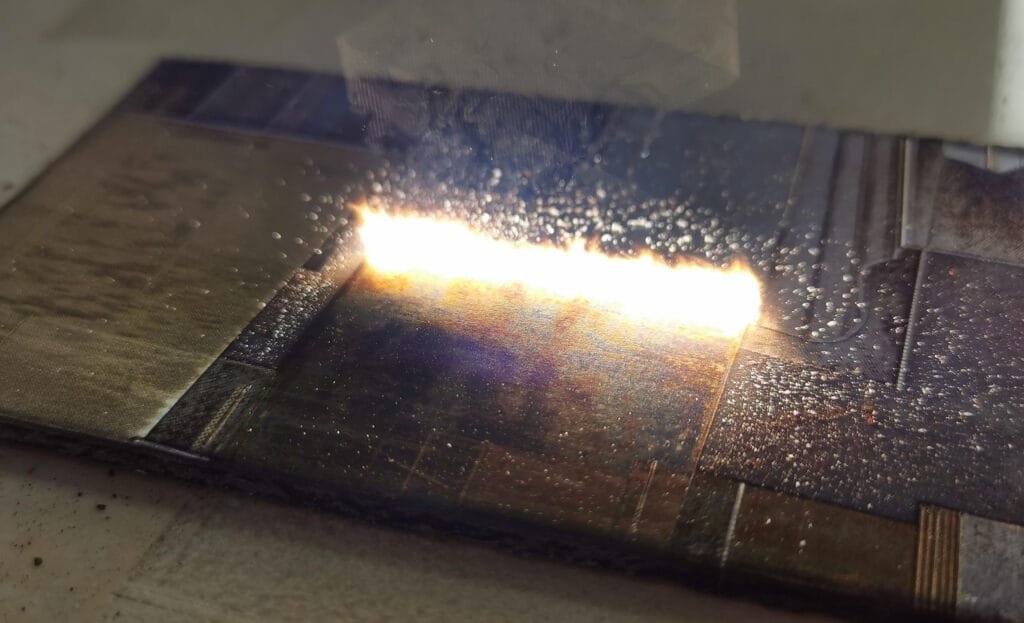

Continuous laser cleaning technology represents a significant advancement in the field of surface cleaning, particularly for industrial applications such as ship descaling. This innovative method utilizes focused laser beams to remove contaminants, rust, and coatings from a variety of surfaces. The basic principle involves directing a high-energy laser beam towards the surface material, where the energy is absorbed by unwanted particles, leading to their efficient removal through vaporization or ablation.

There are several types of laser cleaning systems available, specifically tailored for maritime applications. Continuous wave (CW) lasers and pulsed lasers are the most commonly utilized systems. CW lasers provide a constant beam of light that is effective for consistent cleaning processes, while pulsed lasers deliver concentrated bursts of energy that allow for precise control over the removal process. These systems can be mounted on robotic arms or portable units, making them versatile and adaptable to various cleaning scenarios aboard vessels.

The advantages of employing a laser cleaning machine compared to traditional cleaning methods are numerous. Firstly, lasers offer exceptional precision, allowing operators to target specific areas without damaging the underlying surface, which is crucial for ship maintenance. Additionally, the efficiency of laser cleaning significantly reduces the time and labor required for descaling. Traditional methods often involve harsh chemicals or abrasive tools that can harm both the environment and the integrity of ship materials. In contrast, laser technology is generally cleaner and produces no hazardous waste, making it an environmentally friendly alternative.

Recent technological advancements have further enhanced the viability of continuous laser cleaning for ship descaling. Developments in laser sources, beam delivery systems, and computer control have improved the effectiveness and accessibility of these machines, allowing shipbuilders and maintenance teams to adopt laser cleaning solutions more readily. The integration of this technology into maritime operations not only enhances productivity but also contributes to sustainable practices within the industry.

Benefits of Using Continuous Laser Cleaners for Ship Descaling

Continuous laser cleaners present a range of advantages when utilized for ship descaling, primarily focusing on improving surface preparation. One significant benefit is the ability to effectively remove rust, scale, and other contaminants without damaging the underlying substrates. This precision ensures that ships can maintain their structural integrity and operational efficiency, which is crucial in maritime operations. Enhanced surface preparation leads to better adherence of coatings and treatments applied post-cleaning, ultimately contributing to prolonged asset life.

Moreover, the implementation of laser cleaning technology significantly reduces downtime for maintenance activities. Traditional methods of ship descaling often involve extensive manual labor and the use of abrasive materials, which can lead to lengthy disruptions. Continuous laser cleaners, however, facilitate a faster cleaning process with minimal disruption to operations. This efficiency allows ships to return to service more swiftly, thereby optimizing overall operational capacity and reducing potential revenue loss during maintenance periods.

In addition to operational benefits, continuous laser cleaning machines improve safety protocols for workers. Conventional methods often expose workers to hazardous substances and require protective measures that can complicate the cleaning process. Laser cleaning eliminates the need for chemical solvents and potentially harmful residues, creating a safer working environment. The system’s automated and remote-operation capabilities also minimize human exposure to risks associated with manual cleaning, further enhancing workplace safety.

Furthermore, the use of laser cleaners significantly contributes to waste minimization. Unlike traditional descaling methods which generate substantial waste, laser cleaning is a non-contact method that produces little to no environmental pollutants. This aspect not only aligns with sustainability practices but also reduces disposal costs associated with hazardous waste. The overall reduction in maintenance and repair needs translates into considerable long-term cost savings, making continuous laser cleaners a valuable investment in ship maintenance.

Future Trends and Innovations in Laser Cleaning for Maritime Applications

The maritime industry is undergoing significant transformations, driven by technological advancements and increasing environmental regulations. Continuous laser cleaning machines are at the forefront of this evolution, offering efficient and precise solutions for various applications including ship descaling. As we explore the future of laser cleaning technology within this sector, several trends and innovations emerge that highlight its growing importance.

One notable trend is the integration of laser cleaning machines with other automated cleaning systems. As shipbuilders and operators strive for enhanced operational efficiency, the combination of laser technology with robotic systems is becoming increasingly common. This synergy allows for the automation of repetitive cleaning tasks and can dramatically reduce labor costs while improving safety by keeping personnel away from hazardous working environments.

Furthermore, advancements in laser technology are set to revolutionize the maritime cleaning process. Innovations such as higher-powered lasers and improved beam shaping can increase the cleaning speed and effectiveness, enabling operators to tackle tougher and more entrenched contaminants. The ability to work on various materials without causing damage or altering surfaces will position laser cleaners as a preferred choice for ship maintenance.

In response to the push for greener alternatives in cleaning methodologies, there is also a rising emphasis on environmentally friendly laser cleaning solutions. Continuous laser cleaning machines generate minimal waste and eliminate the need for harsh chemicals, aligning with strict environmental regulations and sustainability goals. Research and development efforts will likely focus on optimizing these systems for enhanced performance and lower energy consumption, further solidifying their role in eco-friendly ship maintenance.

Ultimately, as the maritime industry embraces innovation, continuous laser cleaning equipment is expected to play a crucial role in the future of ship descaling and maintenance. The potential for improved efficiency, safety, and environmental stewardship presents a promising outlook for laser cleaning technology in maritime applications.